The plate nesting module not only reduces the use of steel for production, but also optimizes production times by taking into account the machine capacities during the creation of the nesting by our dedicated algorithm. Programs for the machines are automatically created to ensure maximum productivity.

Our dedicated plate nesting algorithm runs a powerful engine that determines among thousands of solutions the best way to position pieces on a selected plate to optimize the use of steel. Additional parameters can be set to maximize that even more (see further).

For greater flexibility and depending on the way that you organize your production, you can mix parts from different projects on one single plate nesting.

Steel Projects PLM stores all your machines available and their capacities so those are considered while the plate nesting algorithm runs. Therefore, common cuts can be set if you have the actual capacities of doing them in production for example.

Not only the nesting engine optimize the use of steel and save raw material, but it also manages the way the machine will actually perform. For example, starting points can be configured in save time and use of consumables. An emulator is available to visualize production before it begins and adjust machine sequences if necessary.

You can determine the different parameters that will determine if a remnant must go back in stocks or be thrown away. ID numbers are automatically created for the remnants that are kept and then used for next jobs.

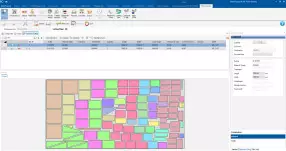

After the nesting is created, you can visualize the future result in 2D.

Steel Projects PLM stores all the tooling operations made by the machines on each part (when and by which operator). Labels can also be printed directly at the station to attach them on parts after being cut.

By integrating stock information, you can decide which steel plate will be used for a particular nesting or decide to order one instead. Those data are updated instantly, whether they come from an external stock management software or ours. Purchase lists can be created easily when orders need to be placed.

You can easily see the status of each nesting (nested, sent to production, processed) with color codes. You can also apply filters to find them quickly according to their status.

You can edit reports that include any information that you may want to include. Those can be cut lists to give to the operators on the machine.

1

Time saving (Drastic reduction of programming times)

2

Flexibility

3

Reduction of scrap rates

4

Improvement of quality of pieces

5

Maximization of machine capacities and consumable use

6

Improvement of traceability management

Need a demo?

Make an appointment with one of our experts to discover how Steel Project PLM will help you better manage your production.