This module is at the heart of the Steel Projects PLM solution. it allows the management and control of ongoing steel fabrication projects or contracts. In one click, access any project and its complete information.

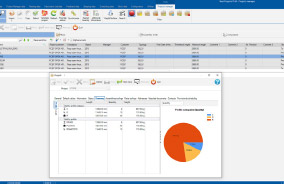

Find under this interface the steel fabrication project nomenclature as it was imported from the drawing software: project / project / phase / assembly / secondary part. These different levels and the elements that compose them are accessible via different tabs to facilitate ergonomics.

Quick access to all useful data to get an overview of the project and help in decision making: name of the project, customer, weight, surface, person in charge, expected delivery date, distribution by profile type, tooling operations required by type, grades, etc.

Recording of all the changes made that are made on a project (What? Who? When?). Quick and visual comparison from one version to another.

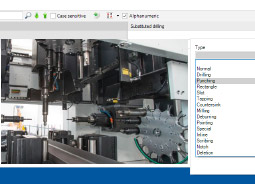

Possibility to modify the tooling operations of a part or a group of parts. Modifications can range from changing the diameter of a hole to replacing one technology with another. For example, converting punching into drilling, or converting notching into scribing (if your machines do not allow, but you want to make it easier for the manual saw station later).

Possibility to attach all useful documents (casting numbers, raw material delivery notes, emails, etc.) of a project in the same location. This ensures that they are not misplaced and increases the level of information available to all project stakeholders. This is also very important for traceability management.

Registration of all types of profiles (Beams, plates, angles, etc.) managed in a database, allowing automatic management of certain parameters based on the software’s recognition of these types of profiles.

Consultation of projects according to their status: to be produced, in production, completed, etc. Application of filters available to find them more easily.

Possibility to create new projects from standard projects or catalogs (particularly useful for manufacturers of transmission towers for example).

1

Time saving

2

Flexibility

3

Simplification of processes

4

Error reduction

5

Ergonomics

6

Reduction of paper use

Need a demo?

Make an appointment with one of our experts to discover how Steel Project will help you better manage your production.