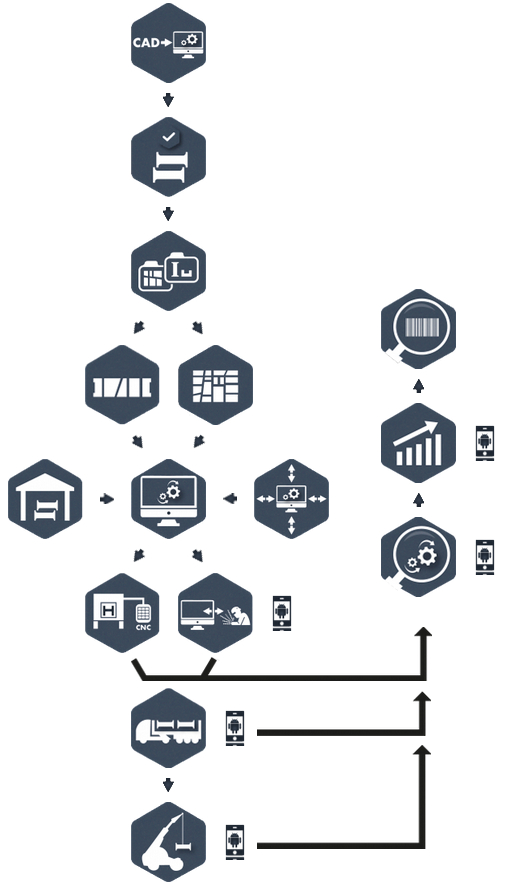

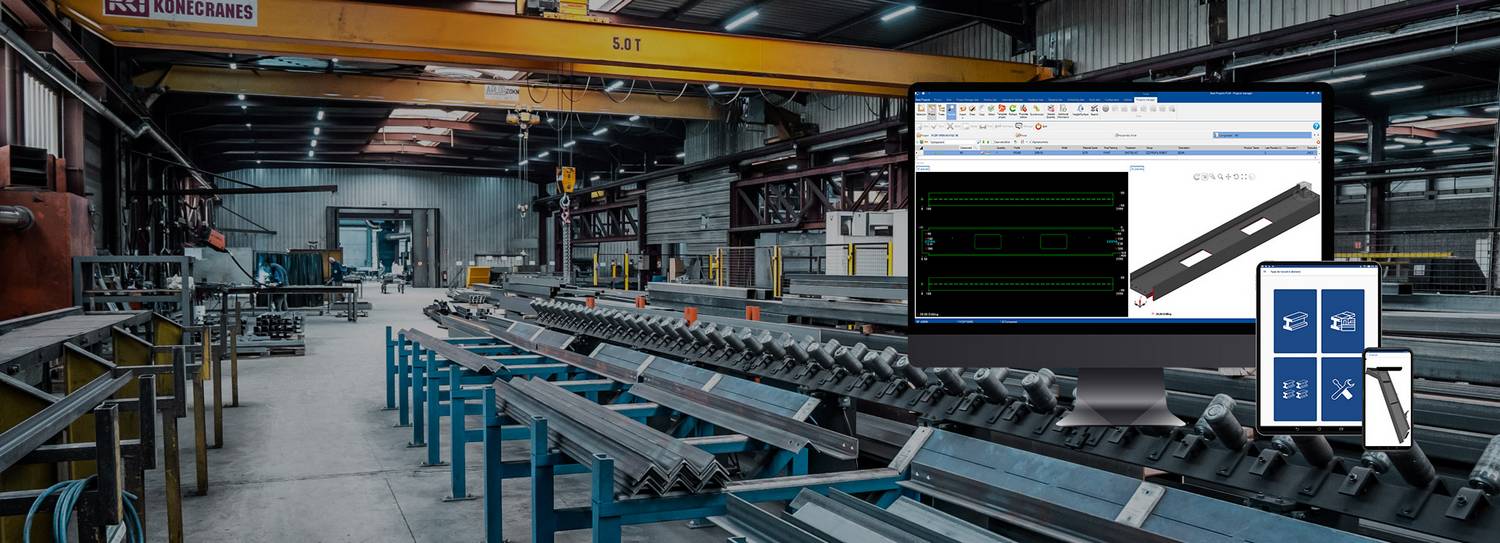

The primary goal of our steel fabrication CAM software is to automate and optimize the link between the detailing office and the steel fabrication workshop by converting drawings into programs for CNC machines, taking into account the constraints in real time. In addition, we develop nesting algorithms (bars and plates) to optimize the use of steel to save raw material and the capacities of the workshop. Finally, our digital solutions allow a total control of the shop floor: from the optimization of the workflows, through the live monitoring of production (CNC machines and manual stations), then the advanced analysis of production, ending with the complete and digitalized management of traceability.

Our software Steel Projects PLM includes a set of modular solutions to meet more precisely the needs of each customer in a steel fabrication industry 4.0 environment. Our range includes the following features: