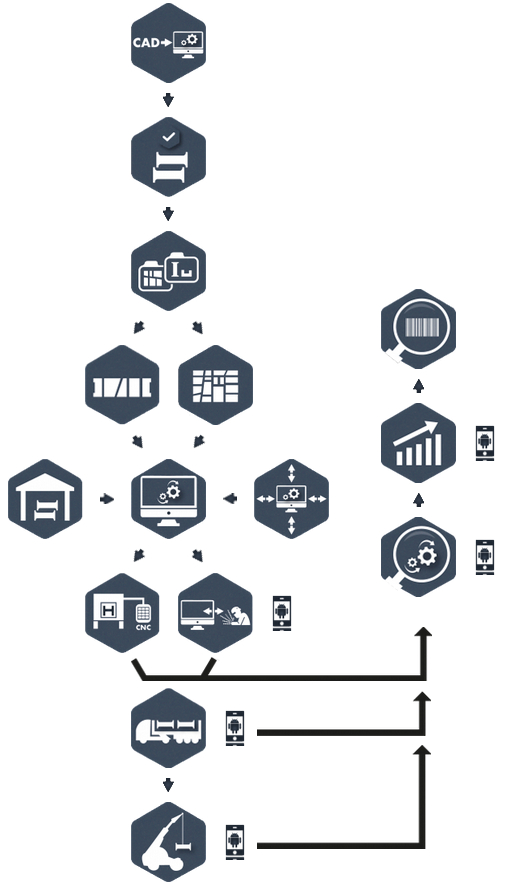

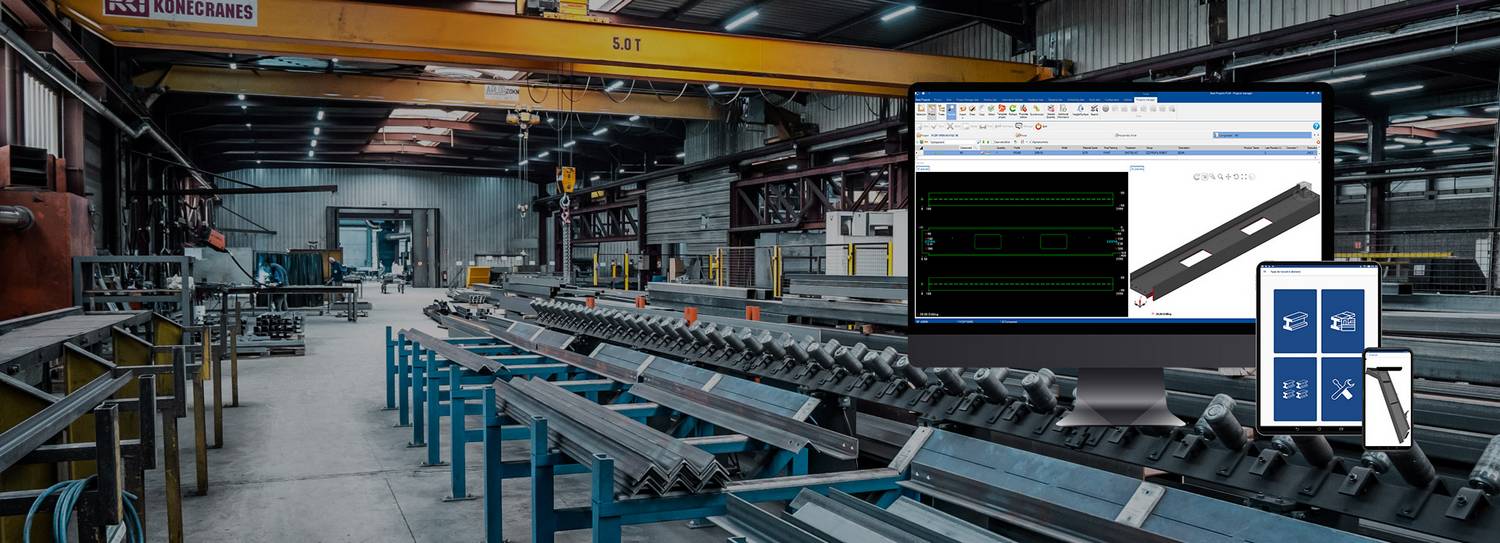

Steel Projects PLM software automates and optimizes the connection between the detailing office and the fabrication plant by converting drawings into programs for CNC machines, taking into account real time constraints. In addition, our software’s proprietary nesting algorithms (bars and plates) optimize the use of steel to save raw material and maximize production capacity.

Moreover, our digital solutions allow comprehensive management of the shop floor.

Our customized modules include the following features: