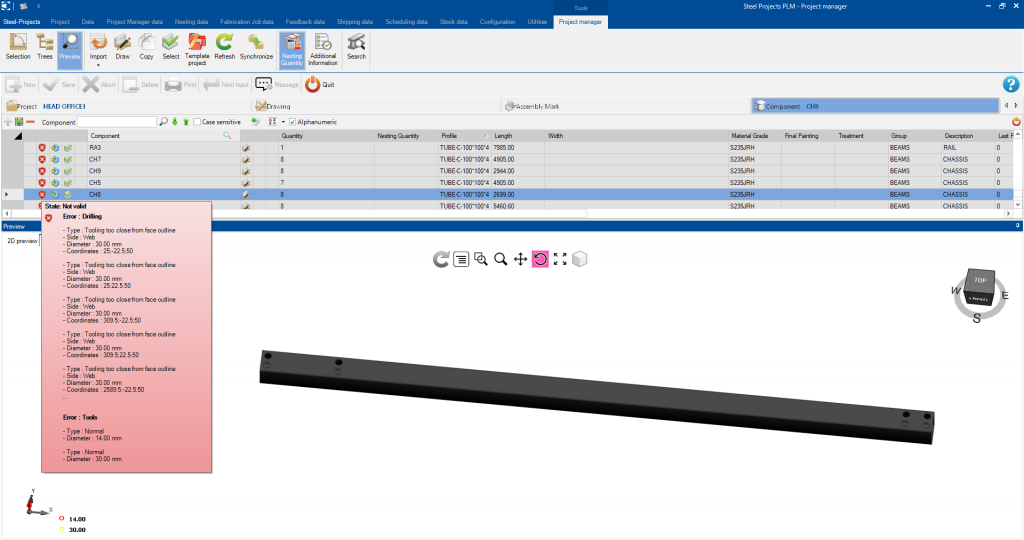

Once the files are imported from the detailing office, they can be checked in several ways before being sent to production.

Through these different operations, you make sure that you only send parts that are compliant and ready to be manufactured!

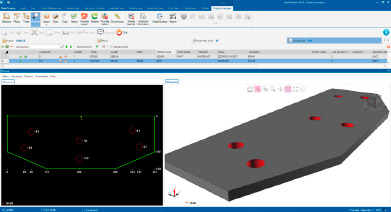

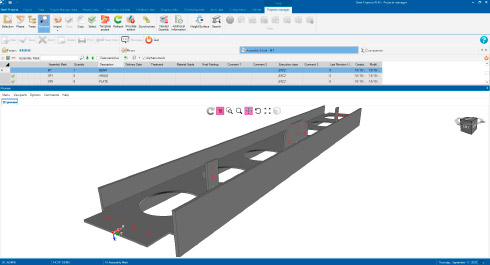

Thanks to the IFC and XML formats that allow to import assembly information, visualize assemblies in 3D and zoom in and out if needed. In addition to a visual control, you can anticipate the different constraints related to this or that assembly on the welding stations.

If you need to make changes to parts, use the drawing module integrated to Steel Projects PLM. Similar to most of common 2D drawing software on the market, it allows you to change tooling operations, dimensions, bends, macros, etc. You can even edit new parts from this module if needed.

1

Time saving

2

Error reduction

3

Flexibility : no need to ask the detailing office for small adjustments

4

Comfort of use thanks to 3D

Need a demo?

Make an appointment with one of our experts to discover how Steel Project will help you better manage your production.