In order to optimize information flows in your company, Steel Projects PLM allows the automatic or semi-automatic integration of data from the detailing office, thus eliminating or limiting data entry operations. In addition to the standard CAD import formats, we have developed more advanced BIM formats that allow you to import even more information.

Steel Projects PLM allows you to import files from multiple detailing software including:

Managed formats are the most commonly used in our sector:

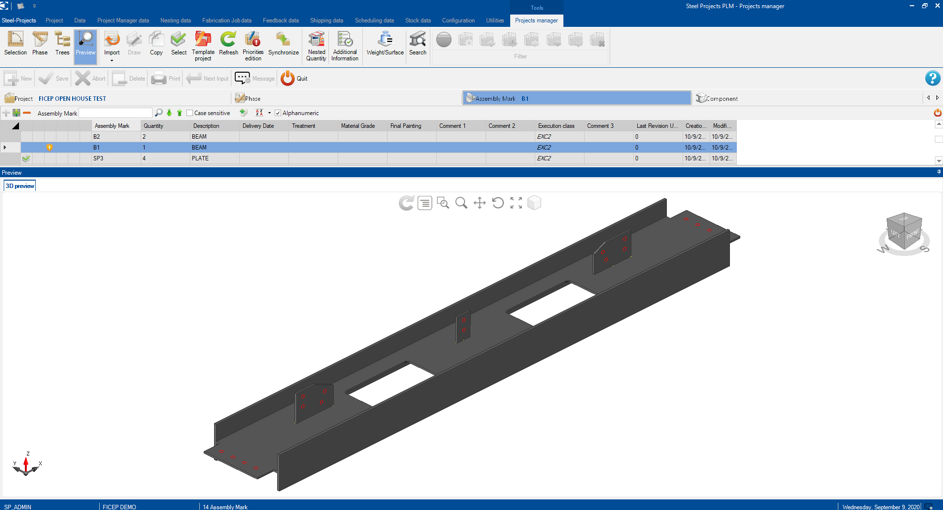

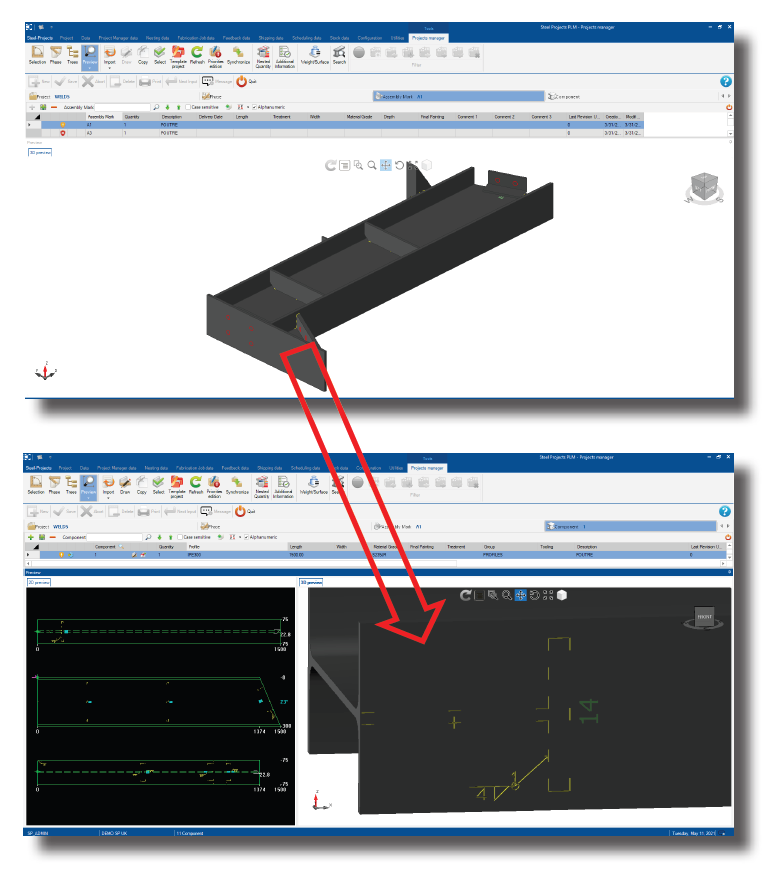

The software analyzes the geometry of each part and then interprets for each one the operations required in production!

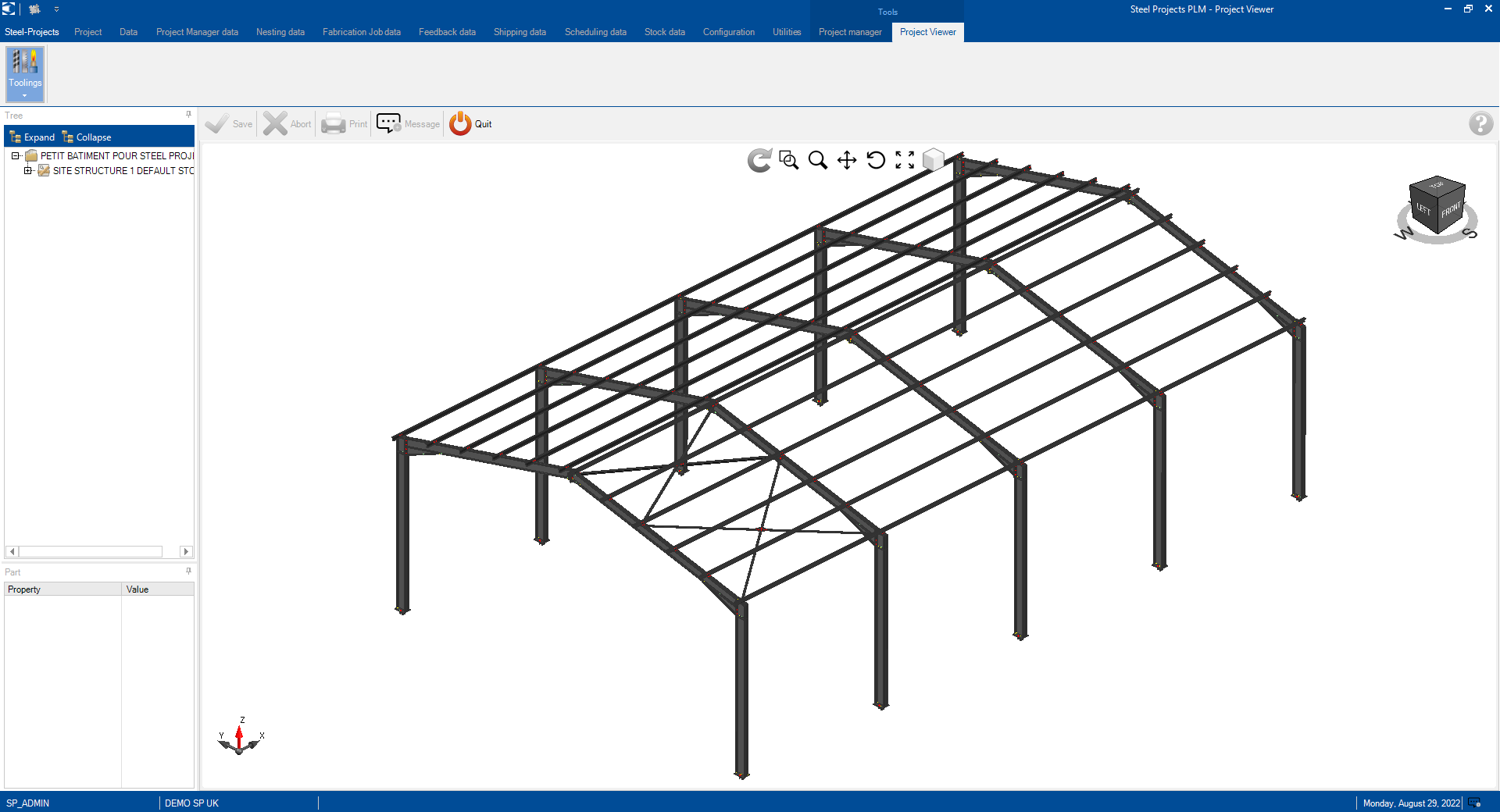

Our software also allows you to import more advanced, modern and scalable formats, called BIM because they are rich in information.

These files integrate the nomenclature of a project or phase, its assemblies and secondary parts, connections between master and secondary parts, planning data and more data from the 3D model. Finally, this type of format allows to import only one file per project, avoiding errors related to DSTV files lost in the process.

In addition to the IFC format (standardized by the American organization BuildingSMART), which is becoming increasingly common in the steel industry, we have developed a special format with Tekla Structures: XML.

Here are some illustrations of the advantages of these two types of files:

The goal will be to achieve considerable productivity gains in the FITTING and welding stations.

1

Time saving

2

Error reduction

3

Flexibility

4

Optimization of information flows between the detailing office and production (digital continuity)

Need a demo?

Make an appointment with one of our experts to discover how Steel Project will help you better manage your production.